Calling all Creators and Makers, introducing the Muse Vision

What is a laser cutter?

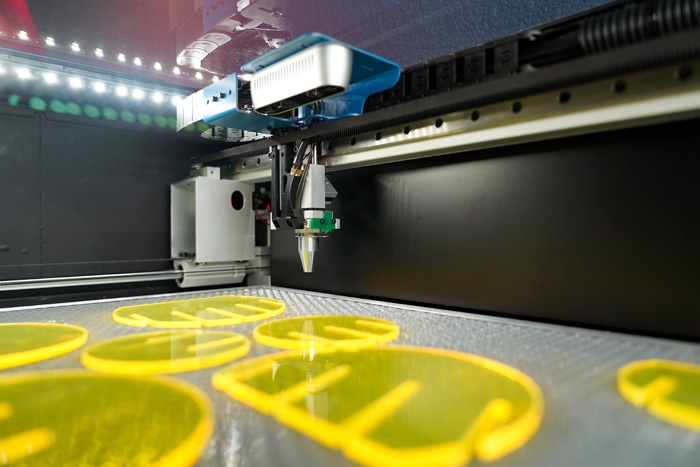

Laser cutters are devices which use focused laser light to cut, etch or engrave a variety of materials. Originally targeted at industrial uses, laser cutters are starting to be used more by the consumer, small shop or maker markets. They’re very versatile, allowing a creator to develop their patterns or designs in a vector package such as Inkscape, Affinity Designer or Adobe Illustrator.* Once a design has been created in that vector package, it’s exported to the laser cutter, which can accept materials as varied as paper, acrylic, wood, glass or leather.

The modern laser cutter provides affordable and easy to use technology that allows creation and replication of beautiful art or complex physical products. Muse laser cutters from Full Spectrum laser put state-of-the art engineering in a full-featured compact package suitable for the home maker or space strapped startup.

How is Intel® RealSense™ technology being used in the Muse Vision?

The Intel RealSense depth camera D435 is being used in the latest Muse laser cutter, the Muse Vision. In order to accurately cut or engrave materials in any laser cutter, the laser must be adjusted to be the right distance from the material. By adding a depth camera, this adjustment can be made automatically and accurately so that the laser is perfectly focused at the right depth every time. Bad laser alignment or depth settings could result in scorched or wasted material, or cuts that go too deep, or not deep enough. Another common mistake is forgetting to focus the laser properly before beginning a job, again, something that’s solved by this automatic focus powered by the depth camera.

Traditionally, laser cutters for the hobby or home market are designed to cut or engrave only flat materials, such as ¼ inch acrylic or wood. This allows for many different creations, but ultimately limits what people can create since all the material must be at the same distance from the laser cutter and must be consistent in depth. The addition of the Intel RealSense depth camera to the Muse Vision cutter opens up opportunities for new designs and new kinds of products.

What sort of creations are possible with the Muse Vision?

With the D435 included in the laser cutter, creators can now integrate 3 dimensional materials with uneven height, allowing for unique creations not possible with other laser cutters. Professional creators and makers can also use the device to expand their markets and product offerings. Cuts and engravings can now be made accurately on curved or other shaped surfaces. The depth camera also helps to improve the accuracy of material alignment, saving in material costs. No need for manual adjustments to the laser focus between materials, better alignment and more flexibility means that this device is significantly more economical for the operator, saving time and money and allowing for great results every time.

Learn more – http://info.fslaser.com/laser-cutter-with-3d-camera

Subscribe here to get blog and news updates.

You may also be interested in

“Intel RealSense acts as the eyes of the system, feeding real-world data to the AI brain that powers the MR

In a three-dimensional world, we still spend much of our time creating and consuming two-dimensional content. Most of the screens